POWDERCOATING

Inspection

We begin by reviewing your parts to understand their condition, material, and any special requirements such as masking, threads, or heat-sensitive components. This ensures proper planning and accurate quoting.

Preparation

Any removable hardware, rubber, bearings, seals, or coatings are removed to expose clean metal. This prevents contamination and ensures the coating bonds correctly.

Cleaning

We dry blast the parts to remove old paint, rust, and corrosion, creating a clean, textured profile that powder can adhere to. Proper prep is the key to durability and long-term performance.

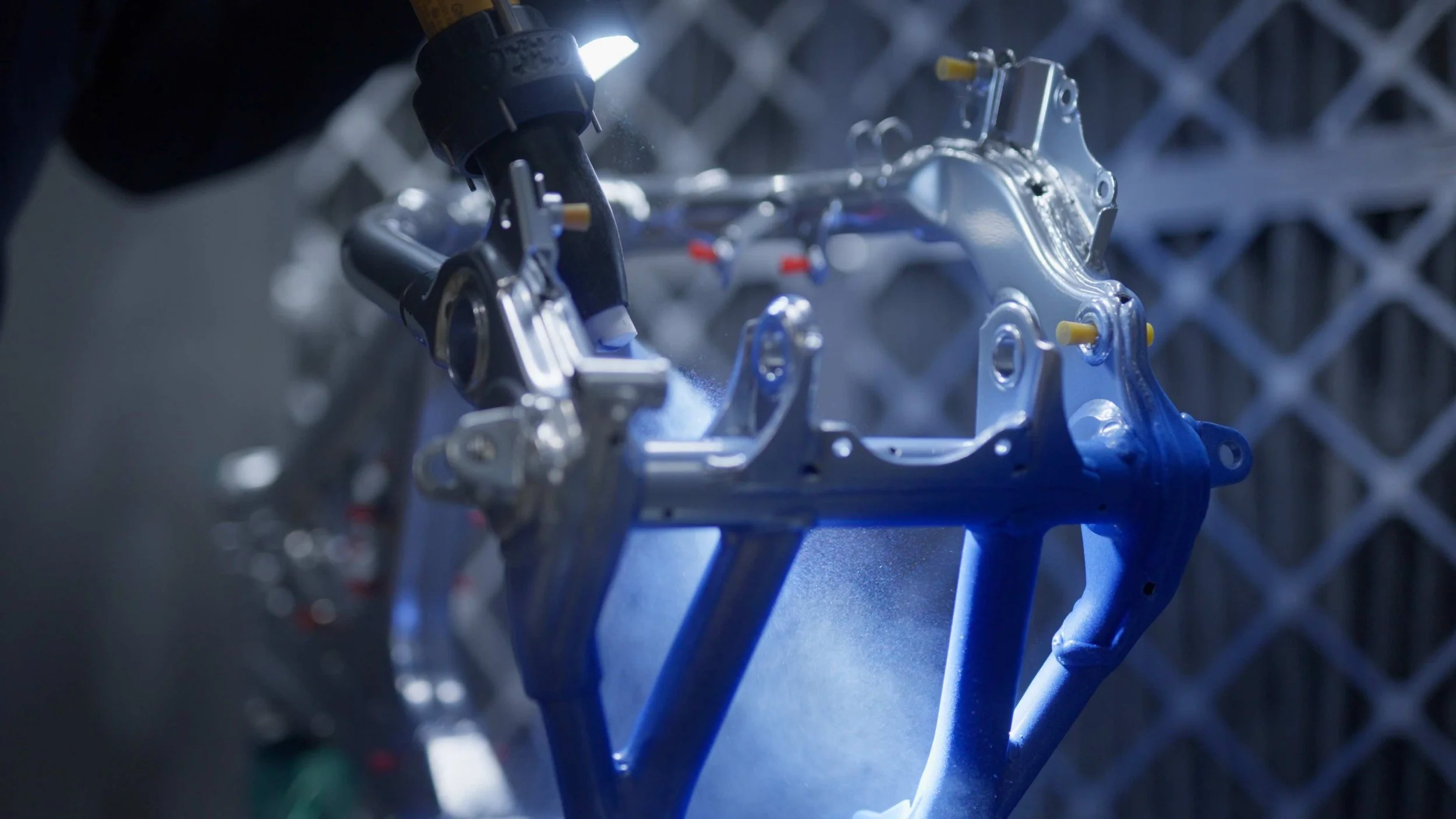

Application

Using electrostatic equipment, powder particles are charged and sprayed evenly onto the grounded metal surface. This creates a uniform, consistent coating across the entire part—even complex shapes.

Curing

The coated parts are heated to the correct temperature, flowing the powder into a smooth continuous film. Once cooled, the finish becomes extremely tough, durable, and long-lasting.

Final Inspection

Every part is inspected for coverage, finish consistency, color accuracy, and surface quality before it leaves our shop.